Welcome to UltraMax TMT

Pioneering Iron & Steel Since 1971

Established in 1971 by Late Shri Bajrang Lal Adukia, Adukia Industries is a leading manufacturer of high-quality iron and steel products. With the support of his wards, Shri Dinesh Adukia, Shri Vivek Adukia, and Shri Gyan Adukia, we have achieved a turnover of ₹25,000 million and built a strong distribution network covering major parts of India. Adukia Industries success is a testament to the founder’s vision, hard work, and commitment to producing superior products that meet the needs of our customers.

Welcome to UltraMax TMT

Pioneering Iron & Steel Since 1971

Established in 1971 by Late Shri Bajrang Lal Adukia, Adukia Industries is a leading manufacturer of high-quality iron and steel products. With the support of his wards, Shri Dinesh Adukia, Shri Vivek Adukia, and Shri Gyan Adukia, we have achieved a turnover of ₹25,000 million and built a strong distribution network covering major parts of India. Adukia Industries success is a testament to the founder’s vision, hard work, and commitment to producing superior products that meet the needs of our customers.

Welcome to UltraMax TMT

Pioneering Iron & Steel Since 1971

Established in 1971 by Late Shri Bajrang Lal Adukia, Adukia Industries is a leading manufacturer of high-quality iron and steel products. With the support of his wards, Shri Dinesh Adukia, Shri Vivek Adukia, and Shri Gyan Adukia, we have achieved a turnover of ₹25,000 million and built a strong distribution network covering major parts of India. Adukia Industries success is a testament to the founder’s vision, hard work, and commitment to producing superior products that meet the needs of our customers.

Our Products

Premium Quality Steel & Iron Products

- TMT Bars

- Pipes & Tubes

- Wire Rods

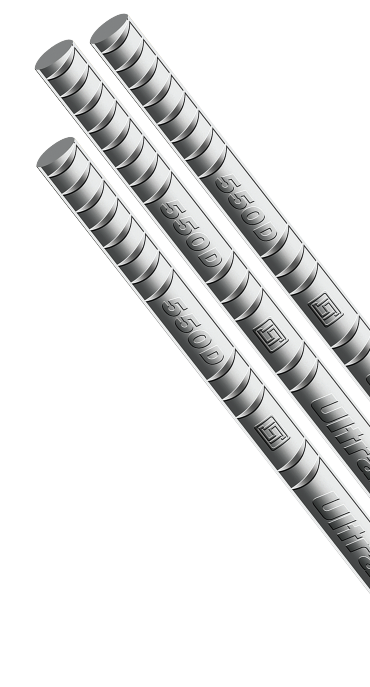

TMT Bars

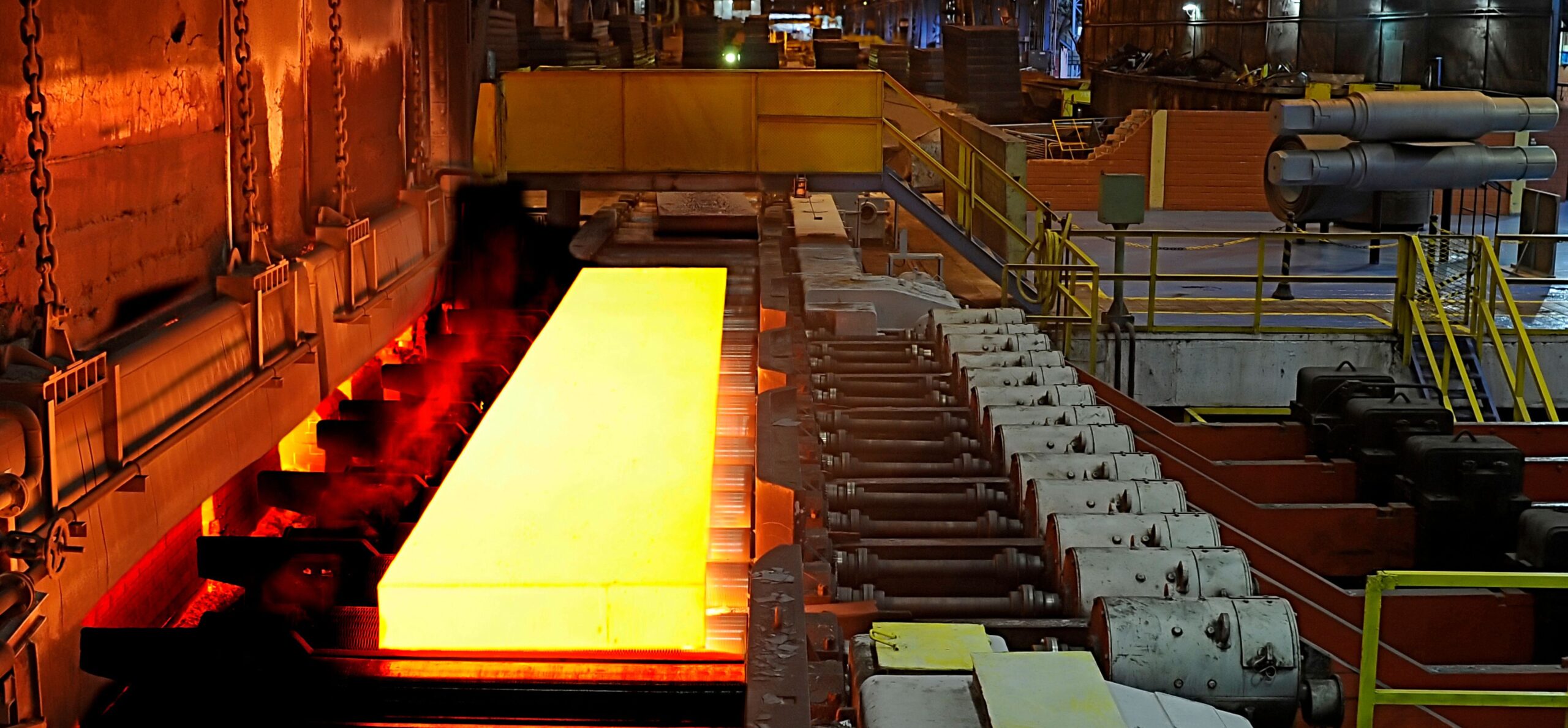

UltraMax has been serving customers from every corner of the country. Our diverse product portfolio has allowed us to serve all sections of the market. Our star product is the UltraMax TMT bar which confirms with IS 1786:2008 latest. UltraMax TMT bars are solid due to their accurate use of necessary constituents during manufacturing and Thermex technology from Hennigsdorfer Stahl Engineering GmbH, Germany.

This production method is among the best in the world, making UltraMax TMT bars an ideal choice.

Our sizes available

- 8mm

- 10mm

- 12mm

- 16mm

- 20mm

- 25mm

- 28mm

- 32mm

Pipes & Tubes

UltraMax is proud to offer a wide section of ERW Pipes that are suitable for transporting gas and oil. The pipes are longitudinally welded and manufactured from strip/coil. This makes UltraMax pipes reliable and efficient in performance in the most demanding conditions. We have the capacity to produce upto 3 inch outside diameter pipes and have the ability to provide a versatile range of options to meet the specific needs of the contractors.

Our sizes available

- 25X25

- 32X32

- 38X38

- 48X48

- 60X60

- 50X25

- 80X40

Wire Rods

UltraMax is a premier manufacturer of iron and steel products. They are committed to delivering cutting-edge solutions for the wire drawing industry. UltraMax wire rods are high-quality stainless rods and HB wires that are used worldwide. We have expertise in heat treatment and hot rolling billets on continuous rolling mills, hence we can produce wire rods and HB wires with the precise chemistry and mechanical properties required for optimal performance.

Our sizes available

- 5.5mm

Our Group Companies

50+

Experience

Explore the Companies Within Adukia Industries

-

N.N. ISPAT PVT. LTD.

-

RAIC INTEGRATED SPONGE & POWER PVT. LTD.

-

AIC IRON INDUSTRIES PVT. LTD.

-

AIC CASTING PVT. LTD.

-

TECH AIC DRI PELLETS PVT. LTD.

N.N. ISPAT PVT. LTD.

N.N. Ispat Private Limited, located in Dewandighi, Burdwan, West Bengal, is a highly reputable manufacturer of TMT bars. With a production capacity of 4,00,000 tons per annum, we produce various high-quality steel products, including TMT bars, billets, wire rods, and HB wires.

Our size range of TMT Bars is 5.5mm to 32mm. We are recognized for our commitment to provide quality products and services at the most reasonable prices.

Expansion: The company is on the way of installing 350 TPD*2 DRI kilns for production of sponge iron and a 25 MW captive power plant.

N.N. ISPAT PVT. LTD.

N.N. Ispat Private Limited, located in Dewandighi, Burdwan, West Bengal, is a highly reputable manufacturer of TMT bars. With a production capacity of 4,00,000 tons per annum, we produce various high-quality steel products, including TMT bars, billets, wire rods, and HB wires.

Our size range of TMT Bars is 5.5mm to 32mm. We are recognized for our commitment to provide quality products and services at the most reasonable prices.

Expansion: The company is on the way of installing 350 TPD*2 DRI kilns for production of sponge iron and a 25 MW captive power plant.

RAIC INTEGRATED SPONGE & POWER PVT. LTD.

RAIC Integrated Sponge & Power Private Limited is located in Jamuria, Burdwan, West Bengal. We have an annual production capacity of 3,00,000 tons of DRI, 3,00,000 tons TMT Bars and 15000 tons of ferroalloys. We have a power plant of 25 MW.

We are expanding to become self-reliant in terms of power supply, contributing to the overall development of India.

Expansion: The company is in process of installing 80,000 tons of DRI with 15 MW captive power.

AIC IRON INDUSTRIES PVT. LTD.

AIC Iron Industries Private Limited located in Purulia, West Bengal has an annual production capacity of 1,20,000 tons of DRI and 2,50,000 tons of mild steel billets, HR narrow strips, and pipes and has a power plant of 25 MW.

Our commitment to quality and state-of-the-art facilities has established us as a reliable supplier of high-quality steel products to various industries.

Expansion: The company is installing a 600 TPD DRI plant for production of DRI.

AIC CASTING PVT. LTD.

This first established unit started its operation in 1971 with the manufacturing of Grey Iron Casting. Presently with 20,000 tons per annum production capacity, with large motor manufacturing companies as its customer base.

Following a strict quality control system and innovative research in the field of iron manufacturing, the Group has opened up three more units to meet the increasing demand and strengthen its distribution channel.

Expansion: The company is establishing its new green foundry at Foundry Park near Kolkata, West Bengal with a capacity of 36,000 tons per annum. The products that will be manufactured are grey iron, ductile iron, alloy castings etc.

TECH AIC DRI PELLETS PVT. LTD.

Tech AIC DRI Pellets Pvt. Ltd., located in Ikrah, West Bengal is engaged in the production of pellets with a capacity of 1.2 million tons per annum.

Expansion: The company is soon coming up with a beneficiation plant.

Why Choose Us

The Choice for Lasting Construction

Download Our Brochure to Explore More

Building for the best

At UltraMax, we are committed to delivering excellence in every project we undertake. With a focus on innovation, precision, and durability, we strive to create solutions that not only meet but exceed expectations.

3200 +

Employee Strength

1 Million MTPA

Combined Production Capacity

45 MW

CPP

600 +

Dealer Network

Certifications

Approved By

CSR

Enhancing

community well-being responsibly.

At the heart of UltraMax’s business lies a strong commitment to nation-building, with a focus on prioritizing our stakeholders, government, shareholders, employees, community, and environment. We aim to foster economic growth while conducting business responsibly and sustainably.

Testimonial

What Our Clients Say

“I must explain to you how all this mistaken idea of denouncing pleasure and praising pain was born and I will give you a complete account of the system, and expound the actual teachings of the great explorer of the truth, the master-builder of human happiness.

No one rejects, dislikes, or avoids pleasure itself, because it is pleasure, but because those who do not know how to pursue pleasure rationally encounter consequences that are extremely painful”.

Fiona D'souza

Video Play

“I must explain to you how all this mistaken idea of denouncing pleasure and praising pain was born and I will give you a complete account of the system, and expound the actual teachings of the great explorer of the truth, the master-builder of human happiness.

No one rejects, dislikes, or avoids pleasure itself, because it is pleasure, but because those who do not know how to pursue pleasure rationally encounter consequences that are extremely painful”.

Dibbendu Biswas

Video Play

Dealership

Join the Ultramax Dealership Network Today

Latest Blogs

Insights, Innovations, and Industry Trends from Ultramax

Exploring the Latest Technological Advancements in Ultramax TMT Bars: A Guide to Enhanced Strength, Durability, and Safety for Building Resilient Modern Infrastructure Projects.

Frequently Asked Questions

Common Queries About UltraMax TMT

Find quick answers to the most frequently asked questions about UltraMax TMT bars, including their benefits, applications, and why they're a top choice for durable construction.-

Q. What makes UltraMax TMT Bars different from other brands?

Ans.UltraMax TMT Bars are known for their superior strength, durability, and resistance to corrosion. Manufactured using advanced technology, these bars ensure high performance and safety for both residential and commercial construction projects.

-

Q. How are UltraMax TMT Bars produced?

Ans.UltraMax TMT Bars are produced using cutting-edge technology, including a quenching and tempering process, which ensures a strong and flexible structure. This results in a product that can withstand extreme pressure and environmental conditions.

-

Q. What are the key benefits of using UltraMax TMT Bars in construction?

Ans.The key benefits of UltraMax TMT Bars include exceptional tensile strength, earthquake resistance, high ductility, and corrosion resistance. These bars also contribute to faster construction and reduced maintenance costs, making them an ideal choice for modern infrastructure projects.

-

Q. Where can I purchase UltraMax TMT Bars?

Ans.UltraMax TMT Bars are available through an extensive network of dealers and distributors across India. You can easily find a local distributor through Adukia Industries’ website or by contacting our customer support team.